Ukumisa Ngaphambilini: Ukugcwalisa Ikesi Lephampu

Ngaphambi aiphampu ye-centrifugal yesiteji esisodwaiqalisiwe, kubalulekile ukuthi isikhwama sepompo sigcwaliswe ngoketshezi eklanyelwe ukuthuthwa. Lesi sinyathelo sibalulekile ngoba iphampu yamanzi eyi-centrifugal ayikwazi ukukhiqiza ukudonsa okudingekayo ukuze kudonsele uketshezi epompo uma i-casing ingenalutho noma igcwele umoya. Ukuqala iphampu ye-centrifugal yesiteji esisodwa, noma ukuyigcwalisa ngoketshezi, kuqinisekisa ukuthi uhlelo lulungele ukusebenza. Ngaphandle kwalokhu, iphampu yamanzi ye-centrifugal ngeke ikwazi ukudala ukugeleza okudingekayo, futhi i-impeller ingase yonakaliswe yi-cavitation-isenzakalo lapho amabhamuza omhwamuma akha futhi awele ngaphakathi koketshezi, okungenzeka kubangele ukuguga okuphawulekayo ezingxenyeni zepompo.

Umfanekiso| Purity Single Stage Centrifugal Pump PSM

Iqhaza Le-Impeller ku-Fluid Movement

Uma iphampu ye-centrifugal yesiteji esisodwa isiqaliswe kahle, ukusebenza kuqala lapho i-impeller—ingxenye ejikelezayo ngaphakathi kwepompo—iqala ukujikeleza. I-impeller ishayelwa yinjini ku-shaft, okuyenza ijikeleze ngesivinini esikhulu. Njengoba ama-impeller blades ejikeleza, uketshezi oluvaleleke phakathi kwawo nalo luyaphoqeleka ukuba lujikeleze. Lokhu kunyakaza kunikeza amandla amaphakathi oketshezini, okuyingxenye ebalulekile yokusebenza kwephampu.

I-Centrifugal force iphusha uketshezi lusuka phakathi nendawo ye-impeller (eyaziwa ngokuthi iso) luye onqenqemeni olungaphandle noma i-periphery. Njengoba uketshezi luphumela ngaphandle, luzuza amandla e-kinetic. Lawa mandla yiwo enza uketshezi luhambe ngesivinini esiphezulu lusuka onqenqemeni olungaphandle lwe-impeller luye ku-volute yepompo, igumbi elimise okusando elizungeza i-impeller.

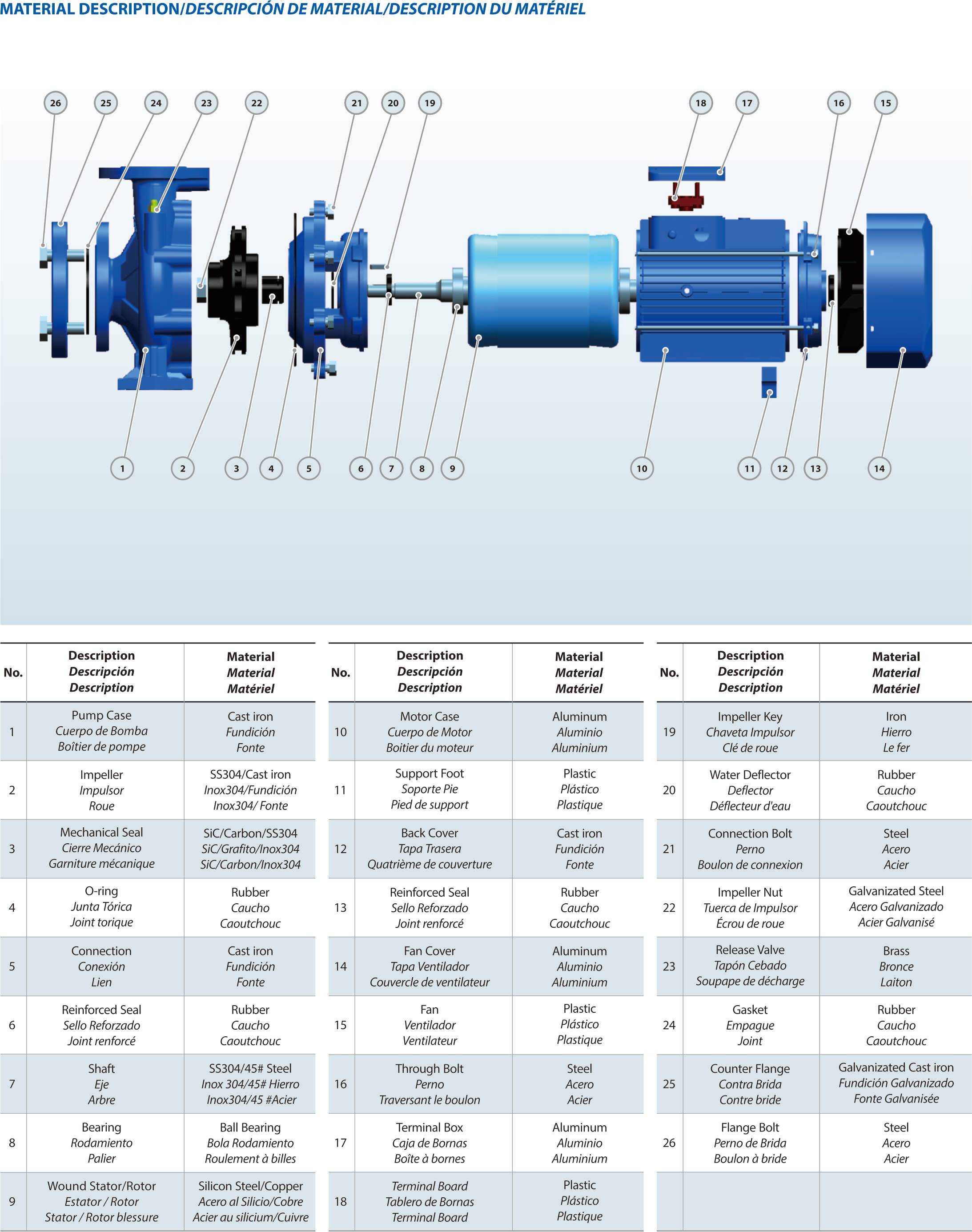

Umfanekiso| I-Purity Single Stage Centrifugal Pump PSM Components

Ukuguqulwa Kwamandla: Ukusuka ku-Kinetic kuya Ekucindezelweni

Njengoba uketshezi olunesivinini esikhulu lungena ku-volute, isivinini salo siqala ukuncipha ngenxa yokwanda kokwakheka kwekamelo. I-volute yakhelwe ukwehlisa uketshezi kancane kancane, okuholela ekuguqulweni kwamanye amandla e-kinetic abe amandla okucindezela. Lokhu kunyuka kwengcindezi kubalulekile ngoba kuvumela uketshezi ukuthi luphushelwe ngaphandle kwepompo ngomfutho ophakeme kunalokho olungenile, okwenza kube nokwenzeka ukuthutha uketshezi ngamapayipi akhiphayo ukuya endaweni yalo ehlosiwe.

Le nqubo yokuguqulwa kwamandla ingesinye sezizathu ezibalulekile zokuthi kunganiamaphampu amanzi centrifugalzisebenza kahle kakhulu ekuhambiseni uketshezi ebangeni elide noma ezindaweni eziphakeme. Ukuguqulwa okushelelayo kwamandla e-kinetic abe yingcindezi kuqinisekisa ukuthi iphampu yamanzi eyi-centrifugal isebenza kahle, kunciphisa ukulahleka kwamandla futhi kunciphisa izindleko zokusebenza zizonke.

Ukusebenza Okuqhubekayo: Ukubaluleka Kokugcina Ukugeleza

Isici esiyingqayizivele samaphampu amanzi asecentrifugal yikhono lawo lokudala ukugeleza okuqhubekayo koketshezi inqobo nje uma i-impeller isazungeza. Njengoba uketshezi luphonswa ngaphandle kusukela phakathi nendawo ye-impeller, indawo enengcindezi ephansi noma i-vacuum eyingxenye yenziwa esweni le-impeller. Le vacuum ibalulekile ngoba idonsa uketshezi olwengeziwe epompo kusuka emthonjeni wokuhlinzeka, igcina ukugeleza okuqhubekayo.

Ukucindezela okuhlukile phakathi kwendawo ewuketshezi ethangini lomthombo nendawo yokucindezela okuphansi esikhungweni se-impeller kushayela uketshezi kuphampu. Uma nje lo mehluko wengcindezi ukhona futhi i-impeller iqhubeka nokujikeleza, iphampu ye-centrifugal yesiteji esisodwa izolokhu idonsa futhi ikhiphe uketshezi, iqinisekisa ukugeleza okuzinzile nokuthembekile.

Isihluthulelo Sokusebenza Kahle: Ukunakekela kanye nokusebenza Okufanelekile

Ukuqinisekisa ukuthi iphampu ye-centrifugal yesiteji esisodwa isebenza kahle kakhulu, kubalulekile ukulandela izinqubo ezihamba phambili kukho kokubili ukusebenza nokunakekelwa. Ukuhlola njalo uhlelo lokuqala lwephampu, ukuqinisekisa ukuthi i-impeller ne-volute azinayo imfucumfucu, futhi ukuqapha ukusebenza kwenjini kuyizinyathelo ezibalulekile ekugcineni ukusebenza kahle kwepompo nokuphila isikhathi eside.

Ukulinganisa kahle iphampu yohlelo oluhlosiwe nakho kubalulekile. Ukulayisha ngokweqile iphampu ngokuyicela ukuthi ihambise uketshezi oluningi kunalokho ebiklanyelwe kungaholela ekugugeni okudlulele, ukuncipha kokusebenza kahle, futhi ekugcineni, ukwehluleka komshini. Ngakolunye uhlangothi, ukulayisha ngaphansi kwesiteji esisodwa sephampu ye-centrifugal kungabangela ukuthi isebenze ngendlela engafanele, okuholela ekusetshenzisweni kwamandla okungadingekile.

Isikhathi sokuthumela: Aug-15-2024