Do uyazi? U-50% wesamba sikagesi esiphehlwa minyaka yonke sezwe sisetshenziselwa ukusetshenziswa kwephampu, kodwa isilinganiso sokusebenza kahle kwephampu singaphansi kuka-75%, ngakho-ke u-15% wesamba sikagesi esiphehlwa minyaka yonke uchithwa yiphampu. Iphampu yamanzi ingashintshwa kanjani ukonga amandla ukuze kwehliswe ukusetshenziswa kwamandla? Ukusetshenziswa, ukukhuthaza ukonga kanye nokunciphisa i-emission?

01 Thuthukisa ukusebenza kahle kwezimoto

Thuthukisa izinjini zokonga amandla, unciphise ukulahlekelwa ngokuthuthukisa izinto ze-stator, sebenzisa amakhoyili ethusi ahlanzekile ekhwalithi ephezulu, uthuthukise izinqubo zokusonta, futhi uthuthukise ukusebenza kahle; yenza umsebenzi omuhle wokukhetha amamodeli ngaphambi kokuthengisa, okubuye kube usizo olukhulu ekuthuthukiseni ukusebenza kahle kwezinjini.

02 Thuthukisa ukusebenza kahle kwemishini

Thuthukisa inqubo yokuthwala futhi usebenzise ama-bearings anokugxila okuhle ukuze unciphise ukulahlekelwa ukuthwala; ukwenza ukupholisha, ukumboza, nokwelashwa okungagugi ezingxenyeni ezigeleza uketshezi ukuze unciphise umonakalo odalwe imithelela efana ne-cavitation ne-friction, futhi uthuthukise ukusebenza kahle kwepompo Kuphinde kwandise impilo yesevisi yezingxenye. Okubaluleke kakhulu ukwenza umsebenzi omuhle ekulawuleni ikhwalithi ngesikhathi sokucubungula izingxenye kanye nokuhlanganiswa, ukuze iphampu ifinyelele esimweni esihle kakhulu sokusebenza, esinganciphisa ukusetshenziswa kwamandla futhi sithuthukise ukusebenza kahle komsebenzi.

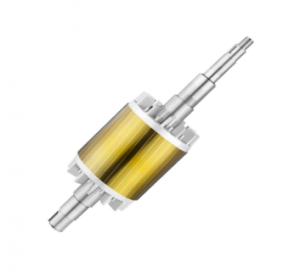

Umfanekiso | Insimbi engagqwali shaft

03 Thuthukisa ukushelela komgijimi

Lapho ucubungula futhi uhlanganisa i-impeller kanye nengxenye yokugeleza ye-blade passage, ukugqwala, isikali, i-burr ne-flash kuyapholishwa ukuze kuncishiswe ukungqubuzana nokulahlekelwa kwe-vortex phakathi kwamanzi nodonga lokugeleza. Ingagxila ezingxenyeni ezibalulekile ezithinta ukusebenza kahle, njengokuthi: i-positive guide vane, ingxenye yokungenisa ye-impeller, ingxenye ye-outlet ye-impeller, njll. Idinga kuphela ukupholishwa ukuze ibone i-metallic luster, futhi ngesikhathi esifanayo, ukuchezuka kwe-scoop ye-impeller akudluli inani elishiwo ukuze kuncishiswe ukulahlekelwa kwe-friction yediski.

Umfanekiso | futha umzimba

04 Thuthukisa ukusebenza kahle kwevolumu

Ukulahleka kwevolumu yephampu yamanzi kubonakala kakhulu ekulahlekeni kwamanzi egebeni leringi yophawu. Uma indawo ehlangene yendandatho yokuvala ifakwe ngendandatho yensimbi futhi “0” indandatho yokuvala irabha ifakiwe, umphumela wokuvala ungathuthukiswa kakhulu, nempilo yesevisi yohlobo olufanayo lwendandatho yokuvala ithuthukiswa kakhulu, engathuthukisa ukusebenza kahle kwephampu yamanzi futhi yehlise izindleko zokuyilungisa. Umphumela uyamangalisa.

Umfanekiso | O indandatho yokukhetha

05 Thuthukisa ukusebenza kahle kwe-hydraulic

Ukulahleka kwe-hydraulic kwepompo kubangelwa umthelela wokugeleza kwamanzi ngomzila wepompo kanye nokungqubuzana nodonga lokugeleza. Indlela eyinhloko yokuthuthukisa ukusebenza kahle kwe-hydraulic yepompo ukukhetha indawo yokusebenza efanelekile, ukuthuthukisa ukusebenza kwe-anti-cavitation nokusebenza kwe-anti-abrasion yepompo, nokunciphisa ukuqina okuphelele kobuso bezingxenye ezidlulayo. Ukuncishiswa kokuqina kungafinyelelwa ngokufaka i-lubricious coating eziteshini zephampu.

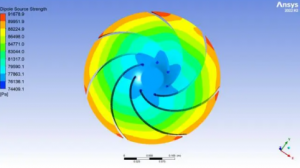

Umfanekiso | I-CFD hydraulic simulation

06 Fukulungiswa kokuguqulwa kwesicelo

Ukusebenza kokulawula isivinini sokuguqulwa kwemvamisa yepompo yamanzi kusho ukuthi iphampu yamanzi igijima ngaphansi kokushayela kwenjini yejubane elungisekayo, futhi indawo yokusebenza yedivayisi yepompo yamanzi iguqulwa ngokushintsha isivinini. Lokhu kwandisa kakhulu ububanzi bokusebenza obusebenzayo bephampu yamanzi, okuyindlela ebaluleke kakhulu futhi esebenzayo yokulungisa kwezobunjiniyela. Ukuguqula i-motor non-speed-regulating motor elawula isivinini, ukuze ukusetshenziswa kwamandla kuhluke ngomthwalo, kungasindisa amandla amaningi.

Umfanekiso | Iphampu yephayiphi yokuguqula imvamisa

Okungenhla ezinye zezindlela zokonga amandla kumaphampu. Thanda futhi unakeUbumsulwaPump Industry ukuze ufunde kabanzi mayelana namaphampu.

Isikhathi sokuthumela: Aug-28-2023