A iphampu yomliloiwucezu lwesisetshenziswa esibalulekile esiklanyelwe ukuhlinzeka ngamanzi ngengcindezi ephezulu yokucisha imililo, ukuvikela izakhiwo, izakhiwo kanye nabantu ezingozini zomlilo ezingase zibe khona. Idlala indima ebalulekile ezinhlelweni zokucisha umlilo, ukuqinisekisa ukuthi amanzi alethwa ngokushesha nangempumelelo uma kudingeka. Amaphampu omlilo awusizo ikakhulukazi ezimweni lapho amanzi asendaweni enganele ukuhlangabezana nesidingo ngesikhathi sezimo eziphuthumayo zomlilo.

Izinhlobo ezimbili ezijwayelekile zamaphampu omlilo

1.Centrifugal Pump

Amaphampu e-Centrifugal asebenza ngokuguqula amandla e-kinetic asuka ku-impeller abe ukucindezela kwamanzi. I-impeller iyaphotha, idonsa amanzi futhi iwakhiphele ngaphandle, idale umfudlana wamanzi anengcindezi ephezulu. Lolu hlobo lwephampu luthandwa ngenxa yekhono lalo lokugcina ukugeleza kwamanzi okungaguquki, ngisho nasezimweni ezihlukene zokucindezela, okulenza lifanelekele izinhlelo ezinkulu zokucindezela umlilo. Ikhono layo lokukhiqiza ukugeleza okuqhubekayo liqinisekisa ukuthi amanzi ahanjiswa ngamandla anele ukuze afinyelele izakhiwo eziphakeme noma amboze izindawo ezinwetshiwe.

2.Positive Displacement Pump

Ngakolunye uhlangothi, amaphampu amahle okuthutha asebenza ngendlela ehlukile. Lawa maphampu ahambisa uketshezi ngokucupha inani elingaguquki futhi abese elukhipha ngohlelo. Izinhlobo ezijwayelekile zihlanganisa amaphampu aphindaphindayo namaphampu ajikelezayo. Indlela eyisisekelo ihlanganisa izinguquko zevolumu ngaphakathi kwegumbi elivaliwe. Njengoba leli gumbi likhula, kwakheka i-vacuum eyingxenye, edonsa amanzi. Lapho igumbi lincipha, amanzi aphuma ngomfutho. Lokhu kulethwa okungaguquguquki, okunemitha yamanzi kwenza amaphampu amahle agudluke abeluleka ikakhulukazi lapho kudingeka ukulawula okunembile kokugeleza kwamanzi, njengamasistimu adinga ukugcina amazinga okucindezela athile ngokuhamba kwesikhathi.

3.Izingxenye Ezibalulekile Nezici

Amaphampu omlilo esimanje, njengalawo asetshenziswa ezinhlelweni eziyinkimbinkimbi zokucisha umlilo, afika efakwe izici zokuphepha ezikhethekile nezindlela zokulawula. Lezi zici ziklanyelwe ukuthuthukisa kokubili ukwethembeka kanye nokusebenziseka kalula ezimeni eziphuthumayo.

Amavalufu Okusiza Ukucindezela: Isici esisodwa esibalulekile sokuphepha ivalvu yokukhulula ingcindezi. Ezimweni eziphuthumayo zomlilo, kusiza ukuvimbela ukucindezela ngokweqile kwesistimu, okungaholela ekulimaleni kwemishini noma ukuhluleka kwesistimu. Ngokugcina ukucindezela kwesistimu okuphelele, lawa ma-valve aqinisekisa ukuthi iphampu yomlilo ingakwazi ukuletha amanzi ngokuqhubekayo ngaphandle kwengozi yokwehluleka. Amasistimu Wokulawula Nokuqapha: Amaphampu omlilo ngokuvamile abhangqwa namasistimu okulawula athuthukile angakwazi ukuqala, ukuma, nokuqapha ngokuzenzakalelayo ukusebenza kwephampu. Lezi zinhlelo zingabandakanya amandla okulawula kude, okuvumela opharetha ukuthi baphathe iphampu bekude.

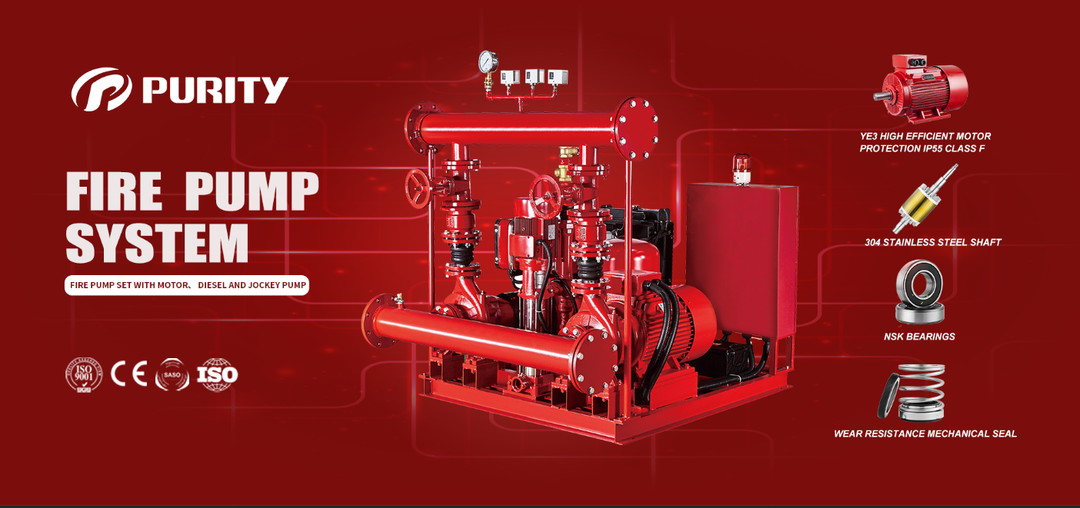

Umfanekiso | Purity Fire Pump-PEDJ

4.Iqhaza Lamaphampu Omlilo Ezinhlelweni Zokucisha Umlilo

Iphampu yomlilo iyingxenye eyodwa nje yesistimu enkulu, ehlanganisiwe yokucima umlilo. Lezi zinhlelo zihlanganisa izifafaza, ama-hydrants, nezinye izakhi ezibalulekile. Ukufakwa okulungile, usayizi, nokugcinwa okuvamile kwephampu yokucima umlilo kubalulekile ukuze kuqinisekiswe ukuthi isistimu iyonke isebenza njengoba kuhlosiwe ngesikhathi esiphuthumayo. Ngokwesibonelo, amaphampu omlilo ayadingeka ukuze ahlangabezane namazinga athile okugeleza kanye namazinga okucindezela asekelwe kusayizi wesakhiwo nesakhiwo. Ukuthobela amakhodi okwakha endawo kanye nemithetho yokuphepha emlilweni kubalulekile. Lawa mazinga aqinisekisa ukuthi amaphampu omlilo angaletha amanzi anele ngesikhathi esiphuthumayo, agcine izinga lokugeleza elidingekayo ukuze kulawulwe noma kucishwe umlilo.

5.Ukubaluleka Kokunakekela Nokuhlola

Ukuqinisekisa ukuthi amaphampu omlilo ahlala esesimweni esikahle sokusebenza, ukunakekelwa okuvamile nokuhlolwa kubalulekile. Lezi zinqubo ziqinisekisa ukulungela kwepompo futhi ziqinisekisa ukuthi ithobelana nezindinganiso zokuphepha. Ukuhlola okujwayelekile kokulungisa kuhlanganisa ukuqinisekisa ukuthi izigxivizo ziqinile, amavalvu asebenza ngendlela efanele, nokuthi akukho ukuvuza ohlelweni. Ukuhlola iphampu ngaphansi kwezimo eziphuthumayo ezilingisiwe kungaphinda kuqinisekise ukuthi izosebenza ngokwethembeka uma idingeka kakhulu.

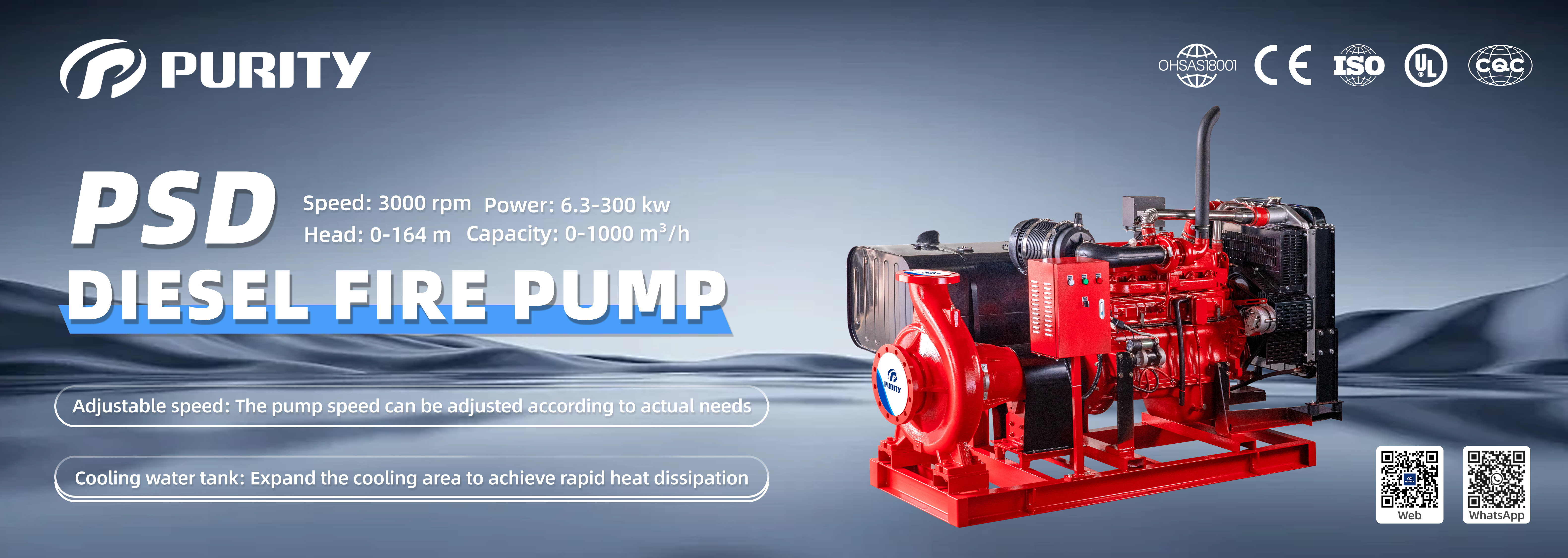

Umfanekiso | Purity Fire Pump-I-PSD

6.Izici zePurity Fire Pumps

Uma kukhulunywa ngabakhiqizi bephampu yomlilo, iPurity igqama ngezizathu ezimbalwa:

(1). Ukusekelwa kwesilawuli kude:Amaphampu omlilo ohlanzekile anikezela ngamakhono okulawula kude, okuvumela opharetha ukuthi baphathe isistimu besendaweni emaphakathi.

(2). Ama-alamu azenzakalelayo kanye nokuvala shaqa: Amaphampu afakwe amasistimu e-alamu azenzakalelayo aqala phakathi nokungasebenzi kahle, okuhambisana nesici sokuvala shaqa ngokuzenzakalela ukuze kuvinjelwe umonakalo.

(3). Ukuqinisekiswa kwe-UL: Lawa maphampu aqinisekiswe nge-UL, ahlangabezana nezindinganiso zamazwe ngamazwe zokuphepha zezinhlelo zokuvikela umlilo.

(4). Ukusebenza Kokuhluleka Kwamandla: Uma kwenzeka kunqamuka ugesi, amaphampu omlilo wePurity ayaqhubeka nokusebenza, aqinisekise ukutholakala kwamanzi okungaphazamiseki ngisho nasezimeni ezimbi kakhulu.

Isiphetho

Njengengxenye ebalulekile yanoma yiluphi uhlelo lokucisha umlilo, amaphampu omlilo abalulekile ekuqinisekiseni ukuphepha ezimeni eziphuthumayo. Kungakhathaliseki ukuthi iyiphampu ye-centrifugal noma i-positive displacement, uhlobo ngalunye lunezinzuzo ezithile ezifanele izimo ezihlukahlukene. Intuthuko yezobuchwepheshe kumaphampu ezicishamlilo, njengemisebenzi yesilawuli-kude, izindlela zokuphepha, nezitifiketi, zithuthukisa nakakhulu ukwethembeka nokusebenza kwazo.

Ngesipiliyoni seminyaka engaphezu kwe-12 ekukhiqizeni amaphampu omlilo, i-Purity isungule idumela lokuhlinzeka ngezixazululo ezinokwethenjelwa nezintsha. Lawa maphampu aklanyelwe ukuhlangabezana nezindinganiso eziqinile zokuphepha futhi aqinisekise ukuthi asebenza ngokwethembeka ngaphansi kwezimo ezidinga kakhulu, okuwenza abe yisinqumo esiphezulu kunoma ubani ofuna ukuthuthukisa izinhlelo zabo zokuphepha emlilweni.

Isikhathi sokuthumela: Dec-16-2023